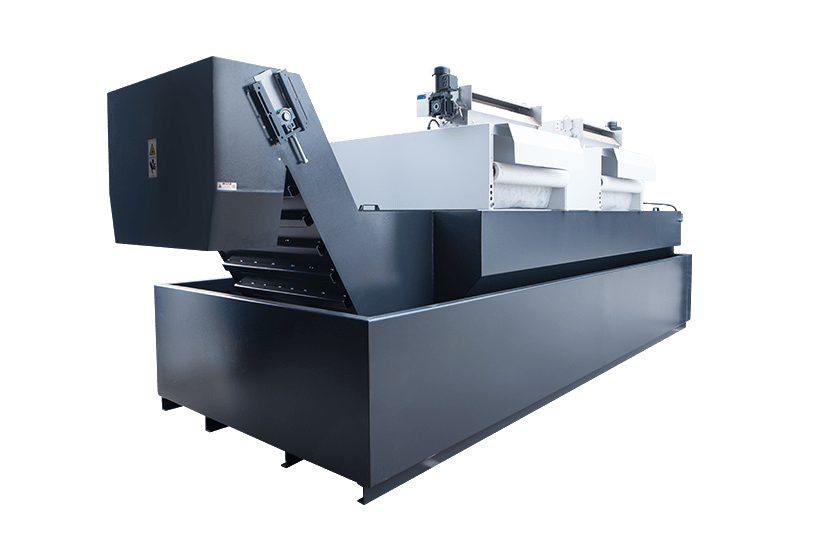

Application

- Central use for several machine tools possible

- Use as a stand-alone cleaning unit, e.g. on machining centers

Properties

- Good price / performance ratio

- Scraper bars and scrapers

- Compact design

- Higher hydrostatic pressure compared to flatbed filters

- Universally applicable for different machining processes, materials, cooling lubricants, volume flows and degrees of purity

Benefit

- Higher volume flow, lower nonwoven consumption and better cleanliness level

- Problem-free discharge of chips, also of light metal

- Space saving installation

- Short amortization period

- Simple layout and planning

Description

Filter process

- Dirty liquid flows laterally through the inlet box into the filter trough

- The filter fleece retains the dirt particles as they flow through it

- The dirt particles form a filter cake that separates even the smallest dirt particles

- The clean liquid collects in the clean tank

Regeneration process

- The growing filter cake increases the flow resistance

- The liquid level in the filter trough increases

- At a defined level, the belt drive switches on (alternatively: time-controlled)

- The carrier belt transports a piece of clean filter fleece onto the filter surface

- The level of the liquid decreases again

- A sludge container or a take-up unit (option) take up the soiled filter fleece